This past Sunday I went on a tour of some cutting edge energy-efficient houses. (They are hoping to meet the Passive House Standard) These photos are of one house in San Jose (1820 Cottle Avenue) by One Sky Homes. It is a conventional, 3200 SF luxury tract home, but will need much less energy to operate. According to the Passive House calculations it will be Net Zero Energy (Solar panels on the roof will provide all the required energy)

So far the house is only partially framed, but we were able to see the advanced framing techniques coming together, including this insulated header:

The house sits a top an insulated crawlspace. This is the first insulated crawlspace I have seen myself. The point of an insulated crawlspace is that all the ducts and water lines can run through conditioned space and energy is not lost. The insulated crawlspace also eliminates some of the thermal bridging that usually occurs where house meets the foundation and the earth. Finally, the conditioned crawlspace stays clean and dry, which makes it far more pleasant when maintenance requires someone to crawl around under the house. Here is a photo looking into the crawlspace from a ventilation hole:

There is, of course, a french drain all the way around the perimeter and also a floor drain in the slab to make sure it stays nice and dry down there.

The walls are insulated concrete forms, and there is 3″ of insulation under the concrete slab as well.

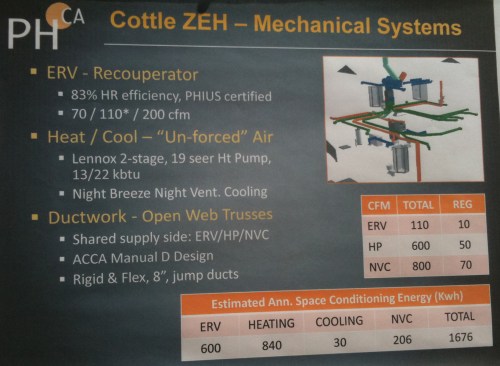

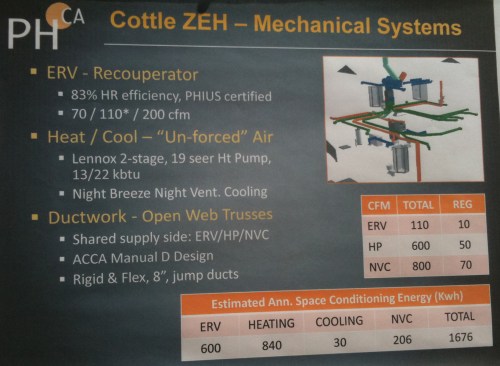

Here is a photo of some of the graphics explaining the heating, cooling and ventilating system:

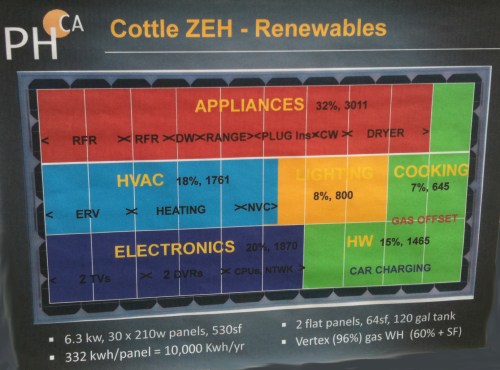

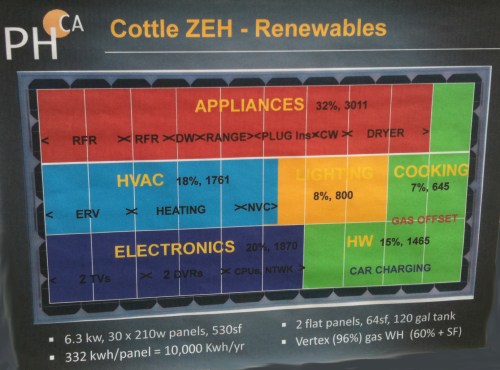

and another showing the anticipated energy breakdown for lighting, appliances, thermal comfort, electric car charging, and entertainment:

Read Full Post »